Content Menu

● Introduction to Emergency Valves

● Design and Functionality of Betts Emergency Valves

>> Key Features of Betts Valves

● Solving Common Industrial Safety Issues

● Regulatory Compliance and Industry Standards

● Case Studies and Real-World Applications

● Future Developments and Innovations

● Conclusion

● Frequently Asked Questions

● Citations:

Industrial safety is paramount in ensuring the well-being of workers and preventing environmental hazards. Emergency valves, such as those produced by Betts Industries, play a crucial role in mitigating risks associated with high-pressure systems. These valves are designed to respond quickly and effectively in emergency situations, thereby safeguarding both personnel and equipment.

Introduction to Emergency Valves

Emergency valves are critical components in industrial settings, particularly in sectors involving high-pressure operations like oil and gas, chemical processing, and transportation. These valves are engineered to activate under specific conditions, such as excessive pressure or temperature fluctuations, to prevent catastrophic failures. Betts Industries, a renowned supplier of emergency valves, offers a range of products designed to meet stringent safety standards and regulations.

Design and Functionality of Betts Emergency Valves

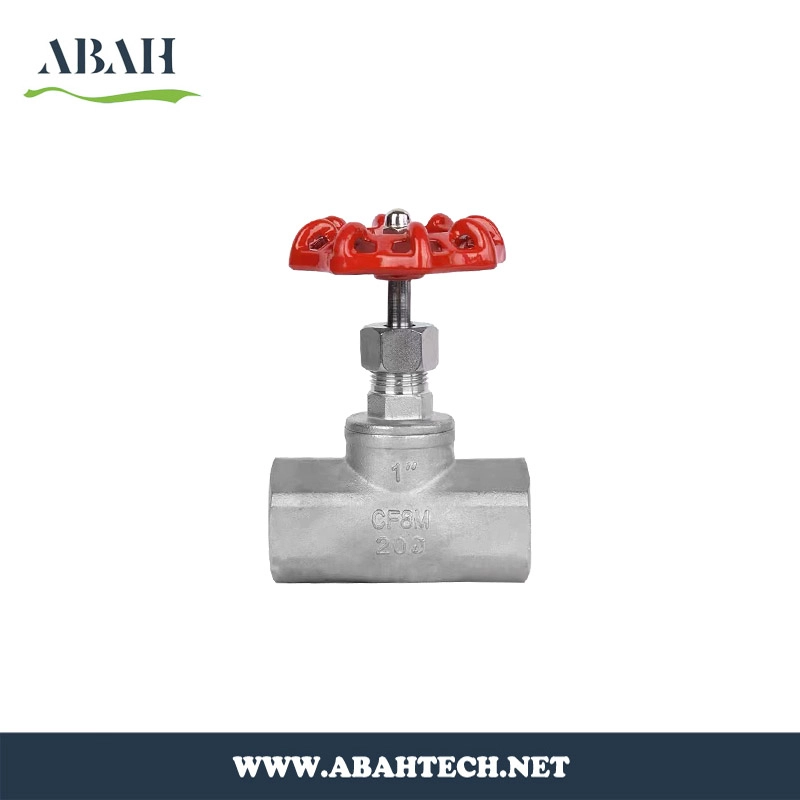

Betts emergency valves are crafted with durability and reliability in mind. They feature robust constructions, often made from materials like aluminum or steel, which are resistant to corrosion and can withstand harsh environmental conditions. These valves are typically operated via cable or air systems, allowing for rapid closure in emergency situations. The inclusion of fusible plugs ensures that the valve can automatically release pressure if exposed to high temperatures, further enhancing safety.

Key Features of Betts Valves

- Material and Construction: Betts valves are built with high-quality materials to ensure longevity and performance under various conditions.

- Operation Mechanism: Cable or air-operated systems provide quick and reliable closure, crucial in emergency scenarios.

- Safety Features: Fusible plugs and shear sections are designed to activate in response to extreme temperatures or accidents, ensuring the valve closes or releases pressure as needed.

Solving Common Industrial Safety Issues

Betts emergency valves address several common safety concerns in industrial settings:

1. Prevention of Overpressure: By rapidly closing or venting, these valves prevent equipment from reaching dangerous pressure levels, thus avoiding explosions or ruptures.

2. Protection Against Fire: The fusible plug feature allows the valve to respond to high temperatures, reducing the risk of fire spreading through the system.

3. Minimization of Environmental Impact: By controlling the release of hazardous materials, Betts valves help mitigate potential environmental damage.

4. Enhanced Worker Safety: Quick response mechanisms ensure that workers are protected from immediate hazards, such as toxic gas leaks or explosions.

Regulatory Compliance and Industry Standards

Betts Industries ensures that its emergency valves comply with relevant industry standards and regulations. For instance, their valves meet HM183 requirements for internal self-closing stop valves and adhere to specific federal regulations like 49CFR178.345-8. Compliance with these standards is crucial for maintaining a safe working environment and preventing legal and financial repercussions.

Case Studies and Real-World Applications

In real-world scenarios, emergency valves have proven indispensable in preventing disasters. For example, in the oil and gas sector, these valves are used to shut off wells in case of emergencies, preventing uncontrolled releases of hydrocarbons. Similarly, in chemical plants, they help manage pressure relief systems to avoid hazardous chemical releases.

Future Developments and Innovations

As technology advances, there is a growing focus on integrating automation and smart systems into emergency valves. This could include remote monitoring and control capabilities, allowing for quicker response times and more efficient maintenance. Additionally, innovations in materials science may lead to lighter, more durable valve constructions that enhance performance while reducing costs.

Conclusion

Betts emergency valves are vital tools in addressing industrial safety challenges. Their robust design, quick response mechanisms, and compliance with industry standards make them essential components in high-pressure systems. As industries continue to evolve, the role of these valves will remain critical in safeguarding lives and environments.

Frequently Asked Questions

Frequently Asked Questions

1. What is the primary function of an emergency valve in industrial settings?

- The primary function of an emergency valve is to quickly respond to hazardous conditions, such as overpressure or high temperatures, by closing or venting to prevent accidents.

2. How do Betts emergency valves comply with industry standards?

- Betts valves comply with various industry standards, including HM183 and 49CFR178.345-8, ensuring they meet rigorous safety requirements.

3. What safety features are typically included in Betts emergency valves?

- Common safety features include fusible plugs that melt at high temperatures to release pressure and shear sections that activate during accidents.

4. Can Betts emergency valves be operated manually?

- Yes, many Betts valves offer manual operation options, such as stainless steel jackscrews, for use in case of air system failures.

5. How do emergency valves contribute to environmental safety?

- By controlling the release of hazardous materials, emergency valves help minimize environmental damage in the event of an industrial accident.

---

Citations:

[1] https://www.csb.gov/assets/1/6/csb_eprs_alert.pdf

[2] https://www.emerson.com/documents/automation/brochure-pwp-series-pressureguard-wellhead-protection-us-bettis-en-85924.pdf

[3] https://www.bettsind.com/valves/

[4] https://parts.krafttank.com/product/betts-6-x-4-90-air-emergency-valves/

[5] https://www.jmesales.com/betts-4-in-flat-seat-aluminum-emergency-valve-cable-operated/

[6] https://www.jmesales.com/betts-4-in-aluminum-internal-air-emergency-valve-elbow-grooved/

[7] https://dixonvalve.com/en/news-and-events/news/dixon-bayco-and-betts-industries-celebrate-20-year-partnership

[8] https://www.olstaco.com/betts-emergency-valve-ev47060aybn/

[9] https://www.nationalboard.org/index.aspx?pageID=164&ID=206

[10] https://www.saferack.com/road-tanker-safety-design-equipment-human-factor/

[11] https://www.wertswelding.com/wp-content/uploads/2020/02/Section1-UPDATED_2.11.20.pdf