Content Menu

● Introduction to Aluminum Seamless Elbows

● Advantages of Aluminum Seamless Elbows

● Applications of Aluminum Seamless Elbows

>> Plumbing Systems

>> HVAC Systems

>> Aerospace Industry

>> Automotive Industry

>> Industrial Processes

>> Marine Applications

>> Food and Beverage Industry

>> Chemical Processing

>> Petrochemical Industry

>> Medical and Laboratory Equipment

>> Construction

>> Telecommunications

>> Renewable Energy

>> Electronics Cooling

● Conclusion

● Frequently Asked Questions

● Citations:

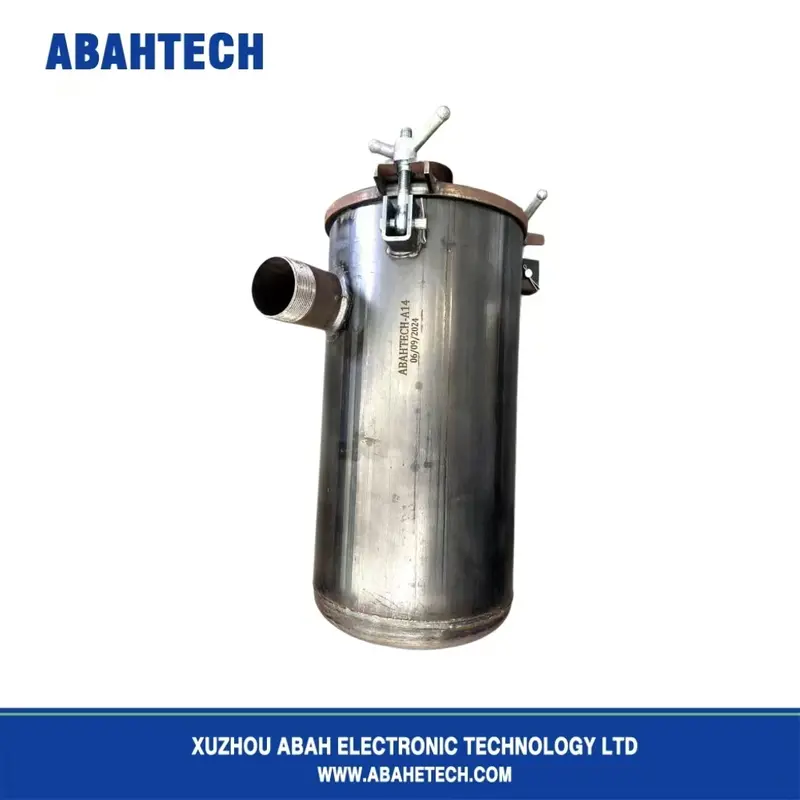

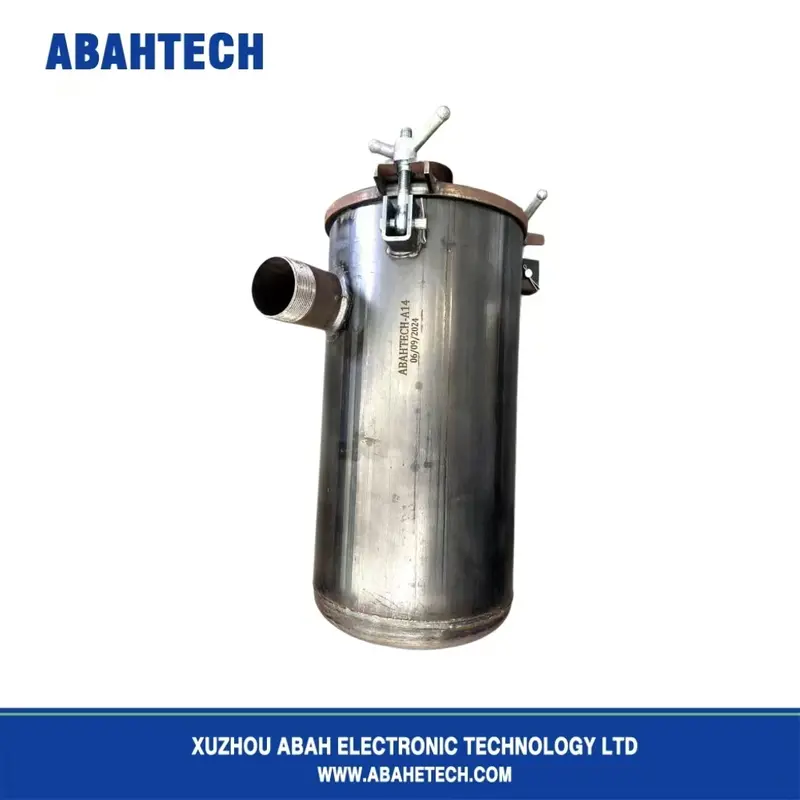

Aluminum seamless elbows are a type of pipe fitting that offers numerous advantages over traditional welded elbows. They are made from a single piece of aluminum, eliminating the need for welds, which can be weak points in the piping system. This design provides high strength, excellent corrosion resistance, and smooth fluid flow, making them ideal for various applications across different industries.

Introduction to Aluminum Seamless Elbows

Aluminum seamless elbows are crafted from high-quality aluminum alloys, such as the 5000 and 6000 series, which are renowned for their excellent corrosion resistance and mechanical strength. These elbows are available in various angles, including 45-degree, 90-degree, and 180-degree configurations, allowing them to be used in a wide range of piping systems. The absence of welds ensures that these elbows have a smooth interior surface, which reduces fluid friction and enhances the efficiency of fluid flow.

Advantages of Aluminum Seamless Elbows

1. Lightweight and High Strength: Aluminum seamless elbows are significantly lighter than their steel counterparts, making them easier to handle and transport. This characteristic is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive manufacturing.

2. Corrosion Resistance: The natural oxide layer on aluminum provides excellent resistance to acids, alkalis, and oxidation, making these elbows suitable for use in humid or corrosive environments.

3. Excellent Thermal Conductivity: Aluminum conducts heat much better than steel, making it ideal for applications requiring efficient heat dissipation, such as in HVAC systems and electronics cooling.

4. Ductility and Versatility: Aluminum is ductile, allowing elbows to be bent and shaped without cracking or breaking. This property enables the fabrication of complex elbow shapes and angles, catering to specific engineering requirements.

5. Non-Magnetic: Aluminum elbows are not magnetic, which is essential in applications where reducing magnetic interference is important, such as in certain scientific and medical devices.

6. Easy to Weld: Although seamless elbows do not have welds themselves, aluminum is readily weldable, allowing for easy assembly with other components or pipes to create complex piping systems.

7. Hygienic: Aluminum is safe and inhibits the growth of bacteria, making it suitable for applications where maintaining hygiene and cleanliness is crucial, such as in the food processing and pharmaceutical industries.

8. Customizability: Aluminum elbows can be custom-designed to meet specific requirements, including unique angles, diameters, and special features.

Applications of Aluminum Seamless Elbows

Plumbing Systems

Aluminum seamless elbows are used in plumbing systems to redirect the flow of water, especially in residential and commercial buildings. They help navigate around obstacles and ensure efficient water flow within the plumbing network.

HVAC Systems

In HVAC systems, aluminum elbows are crucial for changing the direction of air, gases, or refrigerants. They are essential for the proper functioning of heating and cooling systems in residential, commercial, and industrial buildings.

Aerospace Industry

Lightweight materials like aluminum are essential in aerospace applications. Aluminum elbows are used in aircraft and spacecraft for routing fluids, air, and gases within the aircraft's systems.

Automotive Industry

Aluminum elbows are used in automotive exhaust systems to direct exhaust gases away from the vehicle's interior and provide efficient exhaust flow.

Industrial Processes

In industrial settings, aluminum elbows manage and direct the flow of various liquids, gases, or abrasive materials in manufacturing and processing equipment.

Marine Applications

Aluminum elbows are used in marine environments due to their corrosion resistance. They find applications in shipbuilding, offshore structures, and marine HVAC systems.

Food and Beverage Industry

In the food and beverage industry, aluminum elbows convey fluids and maintain sanitary conditions within processing and packaging equipment.

Chemical Processing

Chemical plants and laboratories utilize aluminum elbows to route chemicals and other substances within their processes, benefiting from aluminum's resistance to many corrosive substances.

Petrochemical Industry

In refineries and petrochemical plants, aluminum elbows handle the transportation of various fluids, including petrochemical products.

Medical and Laboratory Equipment

Aluminum elbows may be used in medical and laboratory equipment to control the flow of gases and fluids, often requiring corrosion-resistant and easy-to-clean materials.

Construction

Aluminum elbows can be used in construction for ventilation systems, especially in areas where resistance to rust is important, such as in ductwork and ventilation systems.

Telecommunications

They are used in telecommunications equipment cabinets and enclosures to direct airflow and manage cable routing.

Renewable Energy

In wind turbines and solar power installations, aluminum elbows are employed for air and coolant flow management within the systems.

Electronics Cooling

In electronic enclosures, aluminum elbows help direct cooling air to dissipate heat and maintain the desired operating temperatures of electronic components.

Conclusion

Aluminum seamless elbows offer a versatile solution for fluid and air routing systems across various industries. Their lightweight, corrosion-resistant, and high-strength properties make them an ideal choice for applications requiring efficient fluid flow and durability.

Frequently Asked Questions

1. What are the primary advantages of using aluminum seamless elbows?

- Aluminum seamless elbows offer lightweight, high strength, excellent corrosion resistance, smooth fluid flow, and ease of welding, making them ideal for various applications.

2. In which industries are aluminum seamless elbows commonly used?

- They are commonly used in plumbing, HVAC, aerospace, automotive, industrial processes, marine applications, food and beverage, chemical processing, petrochemical, medical equipment, construction, telecommunications, renewable energy, and electronics cooling.

3. What types of aluminum alloys are typically used for seamless elbows?

- Aluminum seamless elbows are typically made from high-quality alloys such as the 5000 and 6000 series, known for their excellent corrosion resistance and mechanical strength.

4. Can aluminum seamless elbows be customized?

- Yes, aluminum elbows can be custom-designed to meet specific requirements, including unique angles, diameters, and special features.

5. What are the benefits of using seamless elbows over welded elbows?

- Seamless elbows provide higher strength, better corrosion resistance, and smoother fluid flow due to the absence of welds, which can be weak points in welded elbows.

---

Citations:

[1] https://www.marinealum.com/product/aluminum-elbow.html

[2] https://hmaking.com/aluminum-elbow/

[3] https://www.gneepipe.com/news/134.html

[4] https://www.chalcoaluminum.com/knowledge/aluminum-elbow/

[5] https://www.eastern-steels.com/newsdetail/summary-of-the-advantages-of-seamless-elbows.html

[6] https://www.bestar-pipe.com/news/what-are-the-advantages-of-industrial-seamless-steel-elbows/

[7] https://www.eastern-steels.com/newsdetail/the-composition-and-use-of-seamless-elbows.html

[8] https://www.eastern-steels.com/newsdetail/understanding-the-role-of-seamless-elbows-in-piping-systems.html

[9] https://www.hu-steel.com/news364_1488.html

[10] https://metalforgeindia.com/what-is-the-application-of-elbow-fittings/

[11] https://newzelindustries.com/aluminum-buttweld-pipe-fittings-and-its-detailed-information/

[12] https://www.chaluminium.com/what-is-the-difference-between-seamless-aluminum-tube-and-seamed-aluminum-tube

[13] https://cnkpipefitting.com/es/aluminum-5083-elbow-lr/

[14] https://cnkpipefitting.com/aluminum-alloy-elbow-6061-t6-pipe-fittings/

[15] https://www.neoimpex.com/blog/advantages-of-using-45-degree-elbow-in-construction-and-infrastructure-projects/

[16] https://www.maxsteels.com/aluminium-alloy-elbow-manufacturer-exporter.html

[17] https://www.haihaopiping.com/manufacturing-process-of-seamless-elbows.html

[18] https://rulonas.rulonas.com/the-advantages-of-aluminium-in-modern-architecture/

[19] https://www.hu-steel.com/news364_1649.html

[20] https://www.xinqipipeline.com/news/what-is-the-difference-between-welded-elbow-and-seamless-elbow/