Auto Spare Parts Manufacturer – Comprehensive Solution for Trailer and Transport Components

As a trusted Auto Spare Parts manufacturer with nearly two decades of experience, ABAHTECH specializes in producing a wide variety of high-performance trailer and vehicle components. Serving global logistics, agriculture, construction, and petroleum sectors, our parts are known for their durability, precision, and adaptability. Our large-scale facilities, advanced machinery, and strict quality control protocols make us a one-stop solution for all Auto Spare Parts manufacturer needs.

Why Choose Our Auto Spare Parts Manufacturer?

Our extensive expertise as an Auto Spare Parts manufacturer is supported by world-class facilities and a deep commitment to engineering excellence. From semi trailers to fuel tanker parts, each product is manufactured using high-grade materials and advanced production technologies.

Key strengths include:

* Over 100,000 square meters of production area

* 10+ fully automatic production lines

* ISO-compliant quality management

* Customized solutions tailored to your vehicle types and operating environments

* Efficient global delivery for bulk and OEM orders

We understand the critical nature of reliability and compatibility in parts, especially from an Auto Spare Parts manufacturer that serves high-demand industries. That's why our entire product range is built for safety, strength, and long-term performance.

Diverse Product Categories

As a leading Auto Spare Parts manufacturer, we cover an extensive set of categories to support a wide array of transport systems. Below is a detailed look at our major classifications.

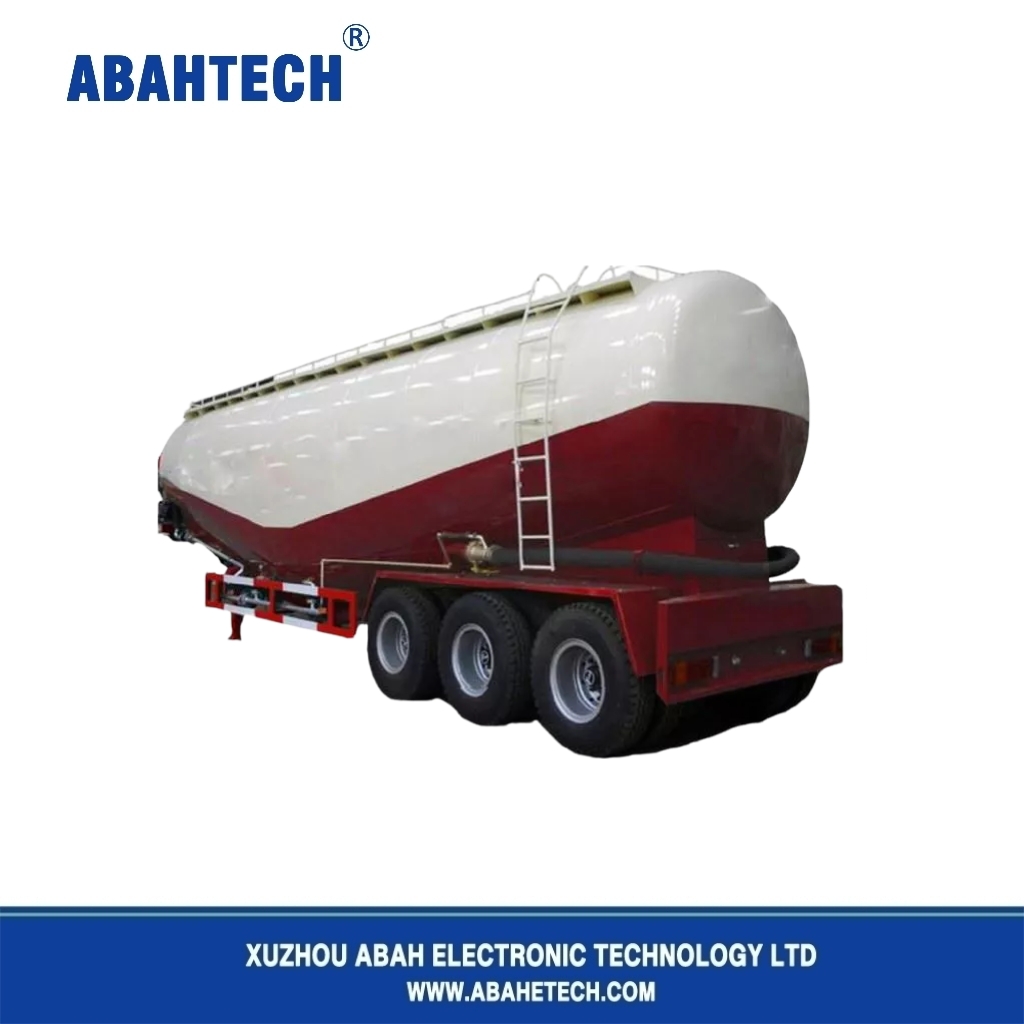

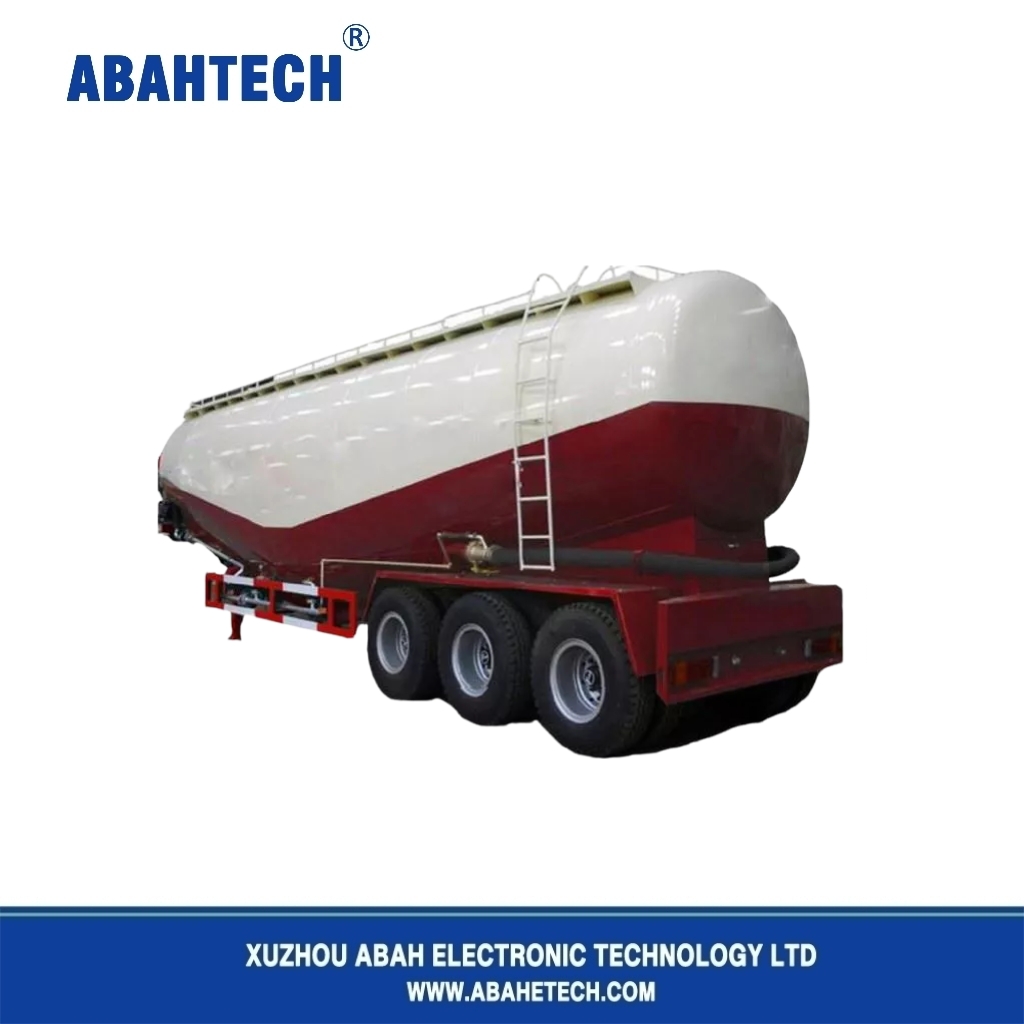

Semi Trailers

We provide robust frames and chassis for various types of semi trailers, including flatbeds, low-beds, bulk carriers, and container carriers. Built using high-tensile structural steel and precision welding, our semi trailers are engineered to endure heavy loads and harsh conditions.

As a seasoned Auto Spare Parts manufacturer, we ensure these structural components meet global safety and performance standards.

Trailer Axles and Components

Our trailer axle assemblies include:

* Axle beams

* Brake drums

* Wheel hubs

* Slack adjusters

* Bearings and brake shoes

Designed for use in tandem or tridem axle systems, our axles are made from forged alloy steel and heat-treated for exceptional strength. Every component reflects the core values of a dependable Auto Spare Parts manufacturer: precision, durability, and reliability.

Suspensions and Components

We offer both mechanical and air suspension systems, including leaf-spring suspension arms, equalizers, air bags, torque rods, and hanger brackets. These suspension parts are essential for shock absorption and maintaining stability during transport.

As an innovative Auto Spare Parts manufacturer, we utilize advanced suspension geometry and stress-tested designs to meet the needs of rough terrain and high-speed logistics.

Landing Gears and Components

Landing gear systems are vital for stabilizing semi trailers during parking or detachment. Our product range includes:

* Two-speed landing gears

* Support legs

* Crank handles

* Gearboxes

Engineered by a professional Auto Spare Parts manufacturer, these components are built from thick-walled steel, zinc-coated for rust resistance, and fully compatible with standard trailer designs.

Leaf Spring and Components

We produce mono-leaf and multi-leaf spring assemblies for trailer and agricultural applications. Each leaf is made from high-quality spring steel, heat-treated for maximum resilience.

As a global Auto Spare Parts manufacturer, we also provide full leaf spring kits including clamps, bushings, and bolts—delivering complete solutions for suspension systems.

Tower Parts and Components

Used primarily in container trailers and intermodal systems, our tower parts include twist locks, turntables, and corner castings. These critical elements are designed and manufactured with the high safety standards expected from a top-tier Auto Spare Parts manufacturer.

All parts are treated with anti-corrosive finishes and undergo fatigue testing to ensure longevity.

Tanker Parts

Our tanker parts range includes:

* Manhole covers

* Bottom valves

* Emergency shut-off systems

* Vapor recovery equipment

* Overfill prevention devices

Produced in stainless steel or chemically resistant alloys, these parts reflect the reputation of an experienced Auto Spare Parts manufacturer trusted by tanker and fuel transport industries worldwide.

Agricultural Trailers and Components

Our agricultural trailer parts are designed to withstand the tough field environment. With years of engineering knowledge as an Auto Spare Parts manufacturer, we supply:

* Trailer axles and suspensions

* Hydraulic lift kits

* Drawbars and hitches

* Chassis frames and wheels

Our parts are corrosion-resistant and built to withstand heavy use across seasonal cycles in various soil and climate conditions.

Other Parts and Components

This category includes brake hoses, air chambers, couplers, fenders, and lighting systems. As a specialized Auto Spare Parts manufacturer, we maintain stock availability and rapid delivery for these essential yet often-overlooked trailer accessories.

Each item adheres to international safety certifications and is rigorously tested before shipping.

Manufacturing Excellence

Every Auto Spare Parts manufacturer is defined by its processes—and ours are driven by quality. Our parts are the result of a seamless, controlled process that includes:

1. Material Selection: High-grade steel, aluminum, HDPE, and composite plastics

2. Forming Methods: Forging, stamping, CNC machining, die casting

3. Finishing Techniques: Galvanizing, powder coating, anodizing

4. Assembly & Testing: Vibration, pressure, corrosion, and tensile testing

5. Customization: OEM fitment, branded packaging, technical drawings

As an established Auto Spare Parts manufacturer, we provide end-to-end production control—from material sourcing to shipment—ensuring consistency and traceability.

Material Advantages

Our expertise as an Auto Spare Parts manufacturer lies in our material science:

* Spring steel: Leaf springs, torque arms

* Forged alloy steel: Axles, kingpins

* Stainless steel: Tanker fittings, couplings

* HDPE: Agricultural and fuel applications

* Aluminum: Landing gear, tower parts

We tailor material properties to the demands of weight load, chemical resistance, fatigue life, and thermal variation.

Application Industries

Our product lineup is tailored to meet the needs of:

* Heavy-duty logistics fleets

* Semi-trailer OEMs

* Construction equipment haulers

* Agricultural implement suppliers

* Fuel and chemical tanker manufacturers

* Spare parts retailers and distributors

As a highly responsive Auto Spare Parts manufacturer, we support both bulk orders and low-MOQ customization.

Industry Advantages

What sets us apart as an Auto Spare Parts manufacturer:

* Wide product coverage across nine major trailer categories

* Competitive pricing with premium build quality

* High-volume production capacity and short lead times

* Global logistics network and on-time delivery

* Custom engineering and technical support

We invest continuously in innovation, automation, and client partnerships to stay ahead as a modern Auto Spare Parts manufacturer.

Article Summary

ABAHTECH is a leading Auto Spare Parts manufacturer specializing in trailer and transport components. With precision manufacturing, advanced materials, and global delivery capabilities, it provides high-quality parts for semi trailers, tankers, and agricultural vehicles.

Come and contact us to purchase!!!