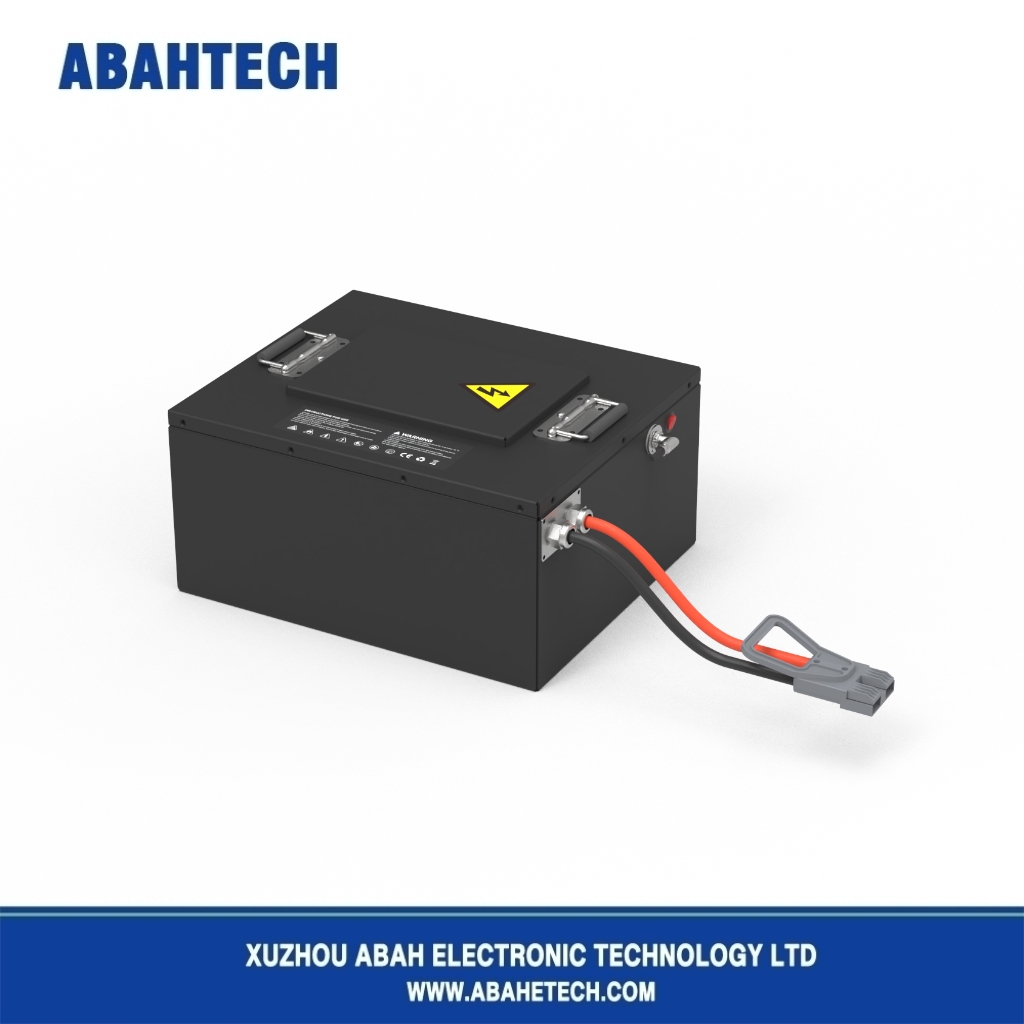

Industrial Special Vehicle Field Battery Manufacturer – Product Overview

Welcome to our flagship product category – Industrial Special Vehicle Field Battery Manufacturer. As a leading Industrial Special Vehicle Field Battery Manufacturer, we are committed to delivering top-tier battery systems specially designed for industrial heavy-duty vehicles operating in harsh field environments. This dedicated section will explore comprehensive details about applications, materials, key features, maintenance, expected lifespan, and advantages in various industries, clearly demonstrating why our offerings stand out in the market.

Applications & Usage Range

Diverse Industrial Vehicle Coverage

As an Industrial Special Vehicle Field Battery Manufacturer, our batteries are engineered for a broad spectrum of demanding industrial vehicles, including:

* Heavy-duty trailers and dump trucks used in construction sites

* Bulk material carriers and silo transport vehicles

* High-altitude operation platforms (cherry pickers, boom lifts)

* Utility and maintenance vans servicing remote facilities

* Defense and military-grade transport units

* Mining machinery (loaders, drills, underground vehicles)

Across all these platforms, our batteries deliver optimum performance, reliability, and endurance. With over 17 years of experience manufacturing automotive and fuel-system components, our Industrial Special Vehicle Field Battery Manufacturer credentials are grounded in solid technical expertise.

Extreme Environment Suitability

Designed to withstand rugged environments, our batteries operate reliably in extreme conditions—wide temperature ranges, heavy vibration, dust, and moisture. As a reputable Industrial Special Vehicle Field Battery Manufacturer, we guarantee functionality even in off-road, underground, or elevated applications.

Construction Materials & Quality Standards

High-Grade Lead–Acid and AGM Technology

Our batteries are built with superior materials:

* High-purity lead alloy plates provide enhanced cycle life and robustness

* Absorbent Glass Mat (AGM) separators offer spill-proof and vibration-resistant performance

* Tough SLA cases made from flame-retardant polymers ensure durability

* Heavy-duty brass or copper terminal inserts resist corrosion and high current

* Dual-layer protective outer casings prevent punctures, chemicals, and environmental damage

By combining advanced AGM and reinforced lead–acid designs, our reputation as an Industrial Special Vehicle Field Battery Manufacturer is built on product reliability.

Precision Manufacturing

At our 103,000 m² production facility, equipped with over 10 precision assembly lines, we ensure consistent quality. As your trusted Industrial Special Vehicle Field Battery Manufacturer, each battery undergoes rigorous testing—capacity, internal resistance, cold-cranking ability—to meet exacting performance standards.

Key Features & Benefits

Superior Performance Characteristics

1. High Cold-Cranking Power

Engineered for instant ignition even at sub-zero ambient conditions—ideal for field equipment facing frigid climates.

2. Deep Cycle Capability

Designed for frequent discharge/charge cycles without damage, perfect for hydraulic or electric systems.

3. Vibration & Shock Resistance

AGM design and rugged casing protect against heavy shaking on uneven terrain.

4. Spill-Proof & Low Maintenance

Fully sealed construction minimizes user handling—critical for industrial environments.

5. Extended Shelf Life

Low self-discharge rates allow storage over months with minimal degradation.

As an Industrial Special Vehicle Field Battery Manufacturer, our systems outclass conventional batteries in reliability and uptime.

Safety & Compliance

* UL and CE certified materials ensure electrical safety

* Non-spill AGM technology meets UN transport regulations

* Equipped with safety valves and flame arrestors to prevent pressure build-up

* Heat-resistant thermoplastic casing resists sparks and electrical faults

These robust safety features reinforce our role as a responsible Industrial Special Vehicle Field Battery Manufacturer.

Maintenance Guidelines

Routine Care & Best Practices

Although AGM batteries require minimal upkeep, the following guidelines extend service life:

* Visual inspections – Check for casing cracks, deformations, or loose terminals monthly

* Voltage check – Use a voltmeter to ensure resting voltage remains between 12.6–12.8 V for 12 V batteries

* Load tests – Run a battery load test annually to verify capacity retention

* Clean terminals – Remove corrosion with a solution of baking soda and water, and apply dielectric grease to seal

* Charge smart – Use temperature-compensated smart chargers; avoid overcharging at high ambient temperatures

Trust our expertise as a premium Industrial Special Vehicle Field Battery Manufacturer to help you preserve battery health and performance.

Expected Service Life

Reliable Longevity

Our robust AGM-based industrial batteries are designed to offer:

* 3–5 years of dependable operation under typical heavy industrial use

* Up to 7 years under optimal conditions (ambient temperatures below 25°C)

* 500–800 deep-cycle discharges at 80% depth-of-discharge (DoD)

Starting from the moment you acquire batteries from our Industrial Special Vehicle Field Battery Manufacturer range, expect sustained and predictable performance over multiple seasons.

Industry Advantages & Competitive Edge

Tailored Solutions for Industrial Challenges

As a renowned Industrial Special Vehicle Field Battery Manufacturer, we provide:

* Customized battery packs to match non-standard voltages or physical dimensions

* Modular configurations for flexibility and scalability

* Quick-connect terminal options, for simplified installation and replacement

* Weatherized housings with UV protection for outdoor use

* Smart integration, supporting Fleet Management systems through optional BMS to monitor charge, temperature, and output in real-time

Cost Efficiency & Operational ROI

* Lower total cost of ownership: fewer replacements, reduced downtime

* Enhanced fuel efficiency: reliable battery power supports optimal engine management

* Lower maintenance costs, thanks to maintenance-free AGM design

* Environmental benefits: recyclable lead plates and sealed construction reduce emissions and acid spills

Trusted Manufacturing Partner

Our credentials as a leading Industrial Special Vehicle Field Battery Manufacturer are reinforced by:

* Over 17 years of experience in heavy-duty vehicle and fuel system component production

* A 103,000 m² facility with advanced manufacturing lines

* Extensive OEM relationships across global markets

* Adherence to strict quality systems: ISO, UL, CE, and UN certification-style compliance

* Strong support network: technical teams, spare parts supply, global logistics

Choosing the Right Battery

Matching Vehicle & Power Requirements

Select models based on:

| Vehicle Type | Voltage | Capacity (Ah) | Dimensions | Typical Part Code |

| Medium trailer / small dump truck | 12 V | 100–150 Ah | 330×172×220 mm | ISVB-12-150A |

| Heavy-duty trailer / silo carrier | 24 V | 200–300 Ah | 500×250×300 mm | ISVB-24-250A |

| Utility platform / van | 12 V | 70–100 Ah | 260×177×220 mm | ISVB-12-100A |

| Start/stop engine systems | 12 V | 150–200 Ah | 400×200×220 mm | ISVB-12-200A |

As a trusted Industrial Special Vehicle Field Battery Manufacturer, we can also offer custom voltages (36 V, 48 V) and non-standard form factors.

Summary & Call to Action

As a premier Industrial Special Vehicle Field Battery Manufacturer, we deliver dependable, high-performance, low-maintenance battery systems tailored for industrial special vehicles. Our expertise in materials, safety design, and after-sales support ensures you receive maximum value and longevity. Whether you operate construction fleets, mining trucks, or elevated platform vehicles, our batteries provide the power you can count on.

We invite you to contact our technical team to discuss your specific field battery requirements—whether it's OEM integration, custom sizing, or ruggedized case design. Choose reliability; choose expertise; choose our Industrial Special Vehicle Field Battery Manufacturer solutions as your trusted energy partner.