Double Wall HDPE Pipe Straight Coupling Product Introduction

As a trusted manufacturer based in China, we are proud to introduce our Double Wall HDPE Pipe Straight Coupling product, which is designed to connect two pipes together. Our innovative solution is perfect for a range of industrial and commercial applications, providing enhanced strength and durability for your piping system.

At our manufacturing facility, we use the highest quality materials to create our Double Wall HDPE Pipe Straight Coupling. This product is constructed from high-density polyethylene, which is known for its excellent durability and resistance to corrosion. This means that our product can withstand harsh weather conditions, as well as exposure to chemicals and other harmful elements.

Our Double Wall HDPE Pipe Straight Coupling is also designed to provide superior strength, thanks to its unique double-wall construction. The inner layer is smooth and ensures that there is no resistance to the flow of fluid, while the outer layer is ribbed, which ensures that the pipe does not collapse during or after installation. This makes our product an ideal choice for areas with high levels of stress or strain on the piping system, such as those with heavy traffic, pressure, or extreme temperatures.

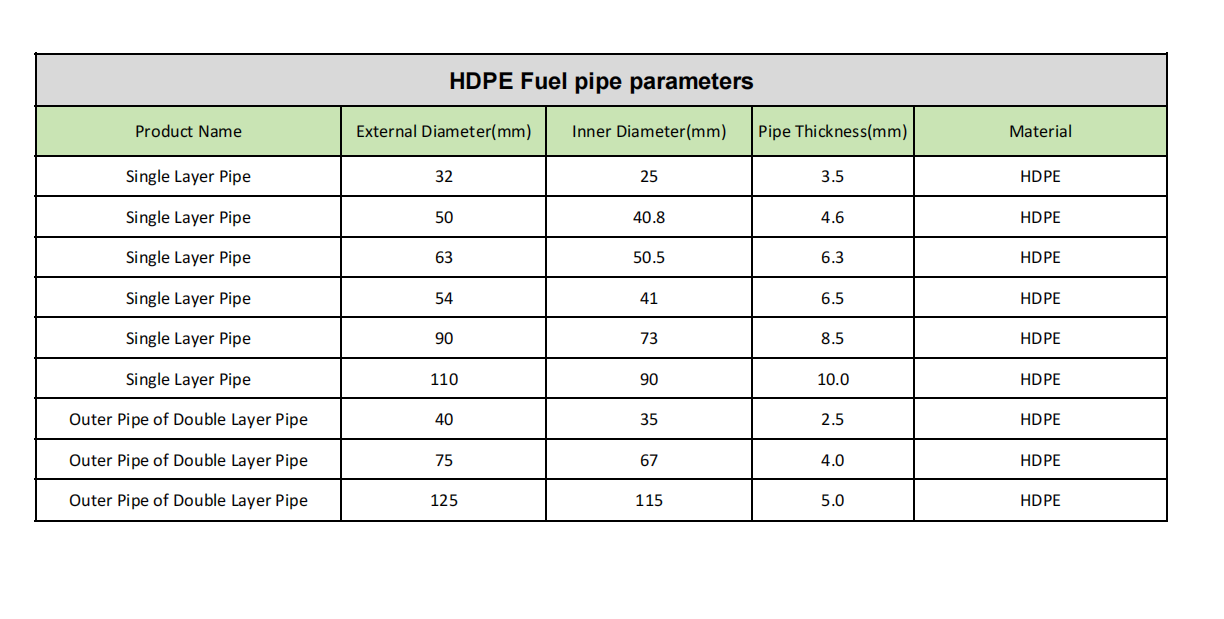

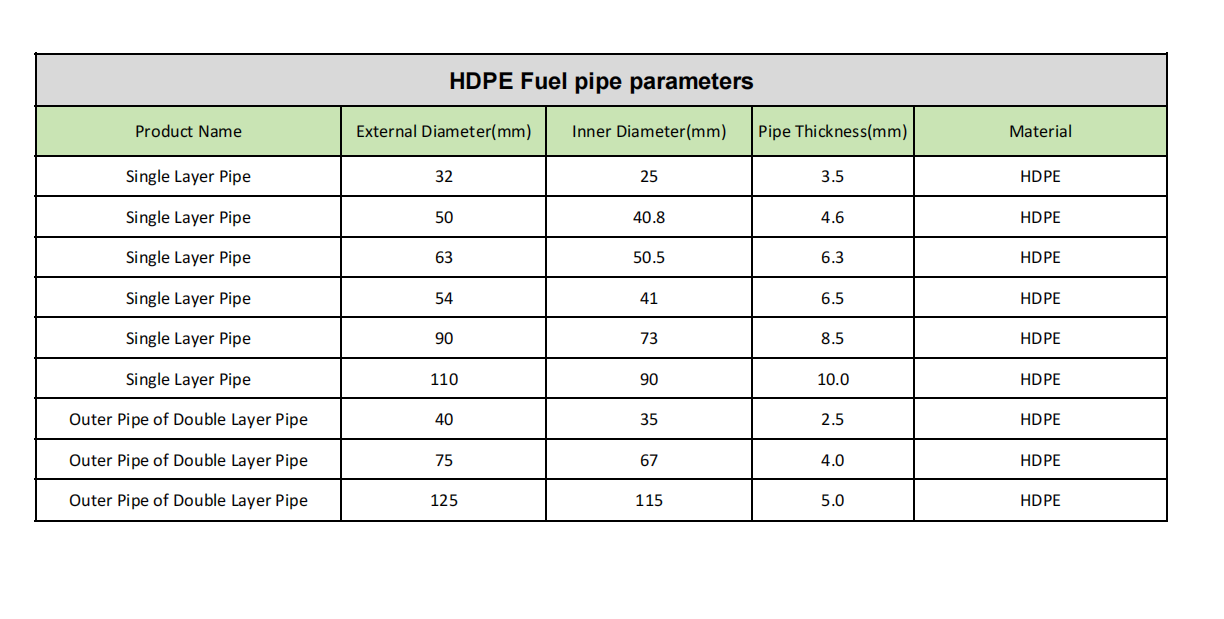

One of the key features of our Double Wall HDPE Pipe Straight Coupling is its easy installation. This product is designed for quick and easy assembly, without requiring any special tools or equipment. It is also available in a range of sizes, making it easy to find the perfect fit for your specific project needs.

Our Double Wall HDPE Pipe Straight Coupling product is suitable for a variety of applications, including drainage, sewage, water supply, and gas transportation. It is also ideal for use in building construction, agriculture, mining, and industrial facilities.

We take great pride in the quality of our products, and our Double Wall HDPE Pipe Straight Coupling is no exception. Our manufacturing process is strictly monitored and controlled to ensure that each product meets our high standards of excellence. Additionally, we are committed to providing exceptional customer service and support, ensuring that you have the information and assistance you need throughout every step of the purchasing process.

In summary, our Double Wall HDPE Pipe Straight Coupling product offers a range of benefits, including enhanced strength and durability, easy installation, and a variety of sizes to choose from. We are confident that this product will meet your specific needs and exceed your expectations, and we look forward to working with you to provide effective and reliable piping solutions for your business. Contact us today to learn more about our products and services, and to place your order.

Double Wall HDPE Pipe Straight Coupling

Gas stations rely heavily on underground transfer pipes to safely transport gasoline and other fuel types from storage tanks to dispensers. However, traditional piping materials like steel and fiberglass can be prone to corrosion and leakage, creating potential hazards for both workers and customers. To mitigate these risks, many gas station owners are now turning to Double Wall HDPE Pipe and Straight Coupling technology.

Double Wall HDPE Pipe is a high-density polyethylene pipe with an outer protective layer and an inner layer that carries the fuel. The outer layer acts as a barrier against moisture and environmental contaminants, while the inner layer resists the corrosive effects of fuel.

Straight Coupling technology is a fitting that connects two pieces of piping together, forming a seamless, leak-proof joint. It is made of the same sturdy HDPE material as the pipe itself and ensures a safe, reliable transfer of fuel between the tank and dispenser.

Together, Double Wall HDPE Pipe and Straight Couplings provide a durable and secure underground piping system that can protect gas stations and their customers from leaks, spills, and other hazardous events. With the ability to withstand a wide range of temperatures and conditions, it's no wonder that more and more gas station owners are choosing HDPE as the piping material of choice for their underground transfer systems.

Our pipes are made of durable materials that hold up well under the harshest environmental conditions.

We have been striving to put the customers on the most valuable position with the best service and quality,and hope to work with all the partners to create a bright future.

Our company has a history of delivering top-quality products and services for our customers.

We are a reliable and qualified supplier, not only can provide high quality products, but also have the fastest delivery speed and the best service.

Our underground fuel transfer pipes offer excellent value for money and are a great investment for businesses of all sizes.

The company has a strong production line and professional sales network, which can produce mature and stable products.

We value our customers and always strive to build lasting relationships based on trust and respect.

We have to achieve quantitative growth while striving to achieve qualitative improvement and ensure the quality of each finished Double Wall HDPE Pipe Straight Coupling.

We stand behind our products and are committed to ensuring your complete satisfaction.

Our company has absorbed a large number of high-quality professional and technical personnel under the business philosophy of 'keeping improving' and the talent philosophy of 'recruiting talents'.

Hot tags:double wall hdpe pipe, pipe coupler, hdpe pipe coupling, gasoline transition fittings, brass pe transition fittings, double wall pipe coupling, gas station pipe, hdpe pipe straight connection, China, customized, discount, manufacturers, factory, price, for sale, suppliers