As a manufacturer located in China, I am proud to offer the 45 degree elbow for gas station HDPE pipe. This product is specifically designed to meet the needs of merchants who are looking for a reliable and durable solution to their gas station piping needs.

The 45 degree elbow is made from high-density polyethylene (HDPE), a thermoplastic material that is known for its strength, durability, and resistance to corrosion. It is the ideal choice for use in gas station piping because of its ability to withstand the harsh environmental conditions that are typical of these types of applications.

One of the key features of the 45 degree elbow is its ability to provide a secure and stable connection between two sections of gas station piping. This is essential for ensuring that there are no leaks or other issues that could compromise the safety of the gas station and its patrons.

Another important aspect of the 45 degree elbow is its ease of use. The product is specifically designed to be easy to install and operate, making it an ideal choice for merchants who are looking for a hassle-free solution to their gas station piping needs.

Of course, safety is always a top priority when it comes to gas station operations. With the 45 degree elbow, merchants can rest assured that they are using a product that has been thoroughly tested and proven to be safe and reliable in real-world conditions.

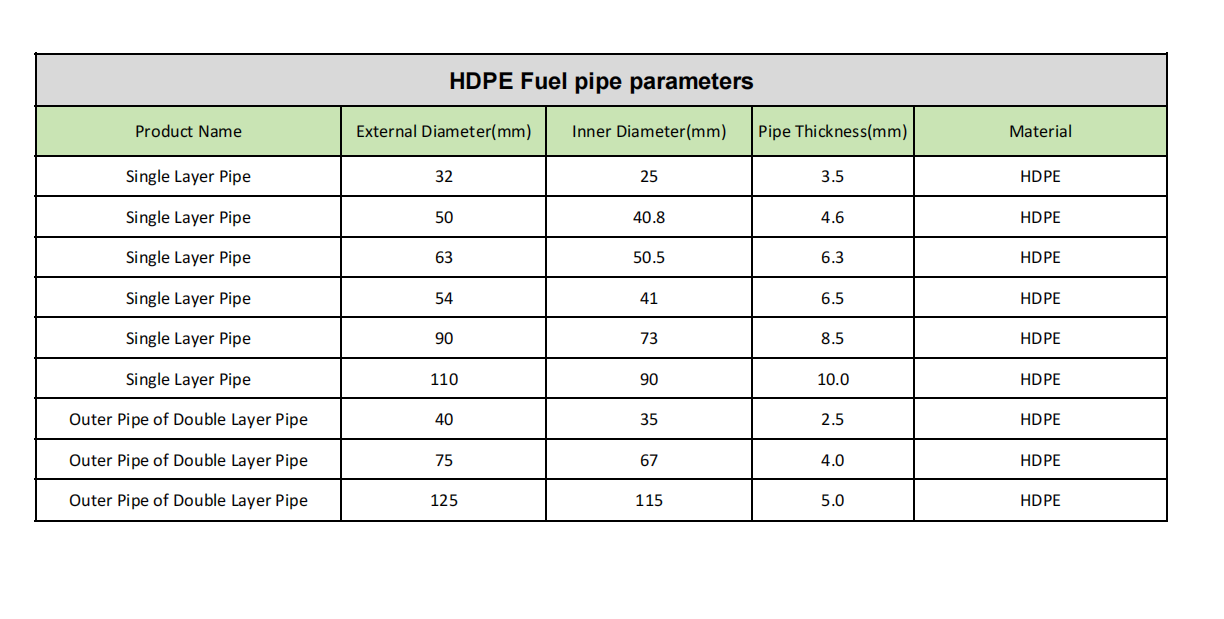

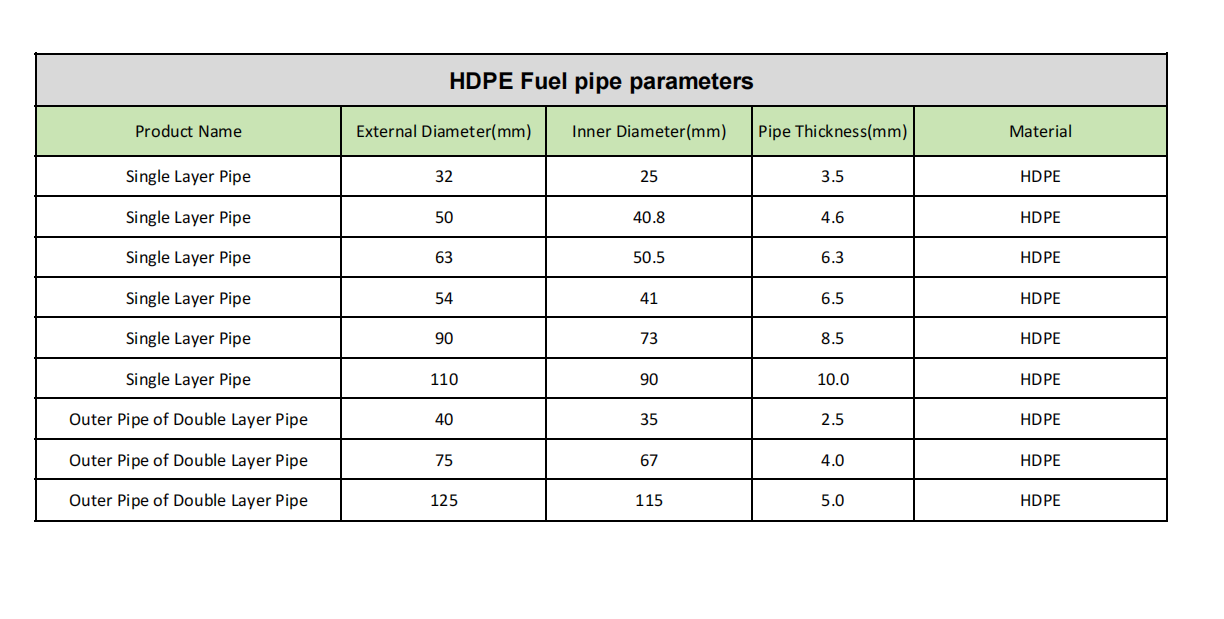

In terms of pricing, the 45 degree elbow is competitively priced, making it an affordable choice for merchants who are looking to minimize their costs without sacrificing quality or performance. It is available in a range of sizes to suit the specific needs of different gas station configurations.

Finally, as a manufacturer, I am committed to providing excellent customer service to all of my clients. Whether you are a small business owner or a larger enterprise, you can count on me to be responsive to your needs and to provide you with the support and assistance that you need to succeed.

In conclusion, the 45 degree elbow for gas station HDPE pipe is a top-quality product that offers merchants a range of benefits and advantages. From its strength and durability to its ease of use and competitive pricing, this product is the ideal choice for anyone looking for a reliable and effective gas station piping solution. So if you are looking for a high-quality product that will help you to achieve your business goals, look no further than the 45 degree elbow.

45 Degree Elbow For Gas Station HDPE Pipe

How do you choose the right petrol station pipeline?

Why PE flexible pipeline not traditional steel pipeline?

There are several reasons why petrol stations choose HDPE pipes over steel pipes:

1. Corrosion resistance: HDPE pipes are highly resistant to corrosion, unlike steel pipes that are prone to rusting and corrosion over time.

2. Light-weight and easy to install: HDPE pipes are light-weight and easy to install as they do not require heavy machinery for installation. On the other hand, steel pipes are heavy and require more labor and specialized equipment for installation.

3. Leak-proof: HDPE pipes are joint-less and have heat-fused joints, which ensure that the pipes are leak-proof. Steel pipes, on the other hand, require welding and can have weak spots which can lead to leaks.

4. Low maintenance: HDPE pipes do not require frequent maintenance as they do not corrode or rust. Steel pipes, on the other hand, require regular maintenance to prevent corrosion and rust.

5. Longer lifespan: HDPE pipes have a longer lifespan than steel pipes as they do not deteriorate over time due to corrosion. This means that petrol stations do not have to replace their pipes frequently, reducing the overall cost of ownership.

Why choose our pipeline?

1. Strong Oil and Solvent Resistance

The special EVOH lining has smooth surface and good oil resistance, which not only helps to reduce the frictional loss in fuel transmission but also totally cut off fuel permeation, thus improving fueling efficiency.

2. Strong Static Conductivity

With advantage of EVOH resign lining, PE pipe has less than 104Ω electrical resistance. Comparison to other materials, PE pipe has more safety for fuel transmission.

3. Excellent Mechanical Property

Applying to Multi-layer co-extrusion techniques to guarantee the strength and durability, our PE pipe has excellent resistance to curve and fracture. It can also bear a pulling force of 7000N, which efficiently prevents oil leakage casing by land subsidence.

4. Strong Corrosion Resistance

The high density polyethylene outer layer has strong corrosion resistance and it can endure the corrosion of various chemical mediators. It has no electrochemical corrosion and never rusts. Compared with metal pipe, polyethylene composite pipe saves much cost for corrosion prevention and reduce much risks casing by pipe corrosion.

5. Wide Range Temperature Suitability

PE pipeline can work well in -40℃ to +50℃ environment without leakage. Its burst pressure which is over 40 standard atmospheric pressure protects the pipeline to perform durably.

6. Super Long Lifetime

The traditional metal pipe generally needs complicated preservative treatment before laying the underground pipes. Even in neutral and non-corrosion soil, the average life of traditional metal pipe is only 10 years. PE flexible pipeline, with PE100 as its outer layer, has a resistance to backfill material and dynamic traffic load. Therefore its life span can achieve 30 years.

We are a Chinese factory that offers high-quality HDPE underground fuel transfer pipes.

The company takes science and technology as the primary productive force, and relies on the leading technology of world-renowned institutions of higher learning in 45 Degree Elbow For Gas Station HDPE Pipe field to carry out long-term close strategic cooperation.

We employ stringent quality control measures to ensure our products meet the highest standards.

Our company is an enterprise specializing in the research and development, manufacturing and operation of 45 Degree Elbow For Gas Station HDPE Pipe, integrating science, industry and trade, and owning the right to import and export.

We are dedicated to providing superior customer service and support.

A strict quality management system has been created to guarantee the caliber of the merchandise.

Our pipes are heavy-duty and can withstand the toughest conditions.

Our company carries forward the enterprise spirit of "integrity, innovation, collaboration, and efficiency", and insists on developing innovative technologies, products, management, and services. While vigorously promoting the quality of products and the internationalization of the market, we strive to build a brand image. We think what our customers think, and we hope to create value for our customers and help them succeed in their business.

We use only the highest quality materials in the production of our underground fuel transfer pipes.

The establishment, survival and development of enterprises are based on capital, which is the lifeblood of enterprise development.

Hot tags:45 degree elbow, 63mm upp pipe, 110mm hdpe pipe, 45 degree bend, petrol station upp pipe fittings, gasoline transfer pe pipe fittings, gas station underground fuel transfer pipe, single wall fuel pipe eblow, China, customized, discount, manufacturers, factory, price, for sale, suppliers