As a manufacturer of 90 Degree Elbow Double Wall HDPE Pipe Fittings, I am proud to offer a high-quality, durable product for merchants outside of China. Our fittings are designed to meet the demands of a wide range of industries, from wastewater treatment plants to agricultural irrigation systems.

One of the key features of our double wall HDPE pipe fittings is their ability to withstand harsh environmental conditions. With a weather-resistant design, these fittings can be used in any climate, making them an ideal choice for businesses operating in diverse areas. Additionally, the use of high-density polyethylene (HDPE) material ensures that our fittings are resistant to corrosion, abrasion, and other forms of wear and tear that can cause damage over time.

Our 90 degree elbow fittings are specifically designed to provide enhanced flow control and system efficiency, making them an excellent choice for businesses looking to optimize their performance. By reducing the risk of blockages and other issues that can impede the efficiency of pipelines, our fittings help businesses save time and money while ensuring that their operations run smoothly and effectively. Additionally, the dual-walled design of our fittings provides extra insulation, helping to maintain the temperature of fluids being transported within the pipeline.

At our factory in China, we use advanced production techniques to ensure that each fitting is of the highest quality. Our team of skilled engineers and technicians oversees each stage of the production process, from initial design to final testing, to ensure that each fitting meets our rigorous standards. We also subject our fittings to independent testing by third-party organizations to ensure that they meet or exceed industry standards.

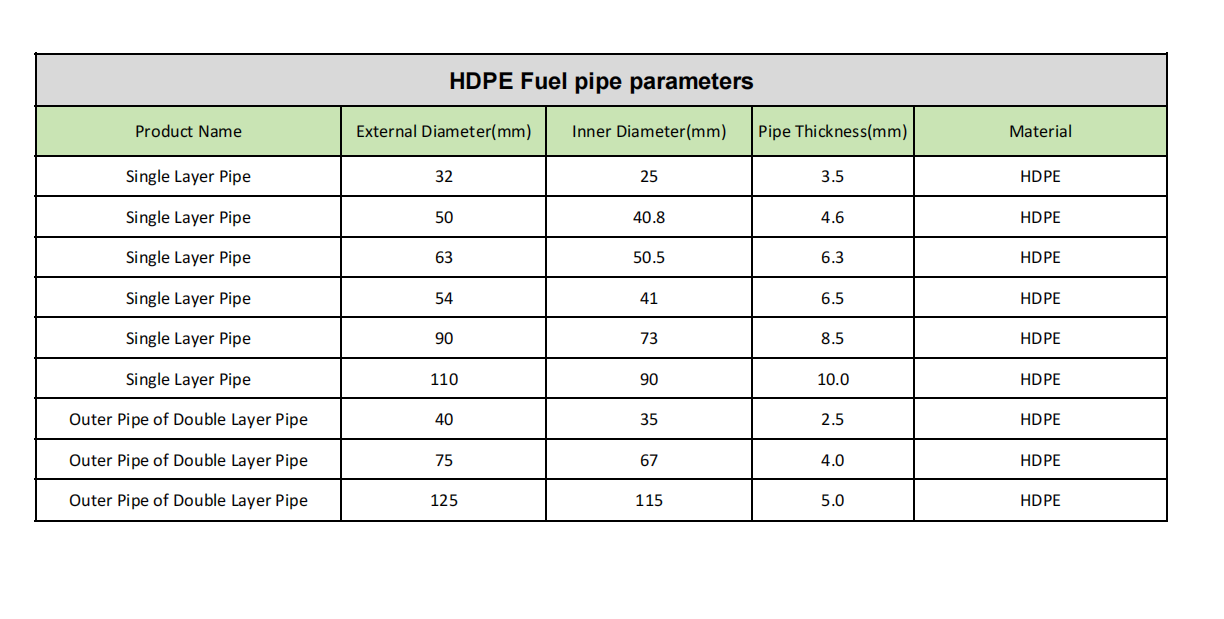

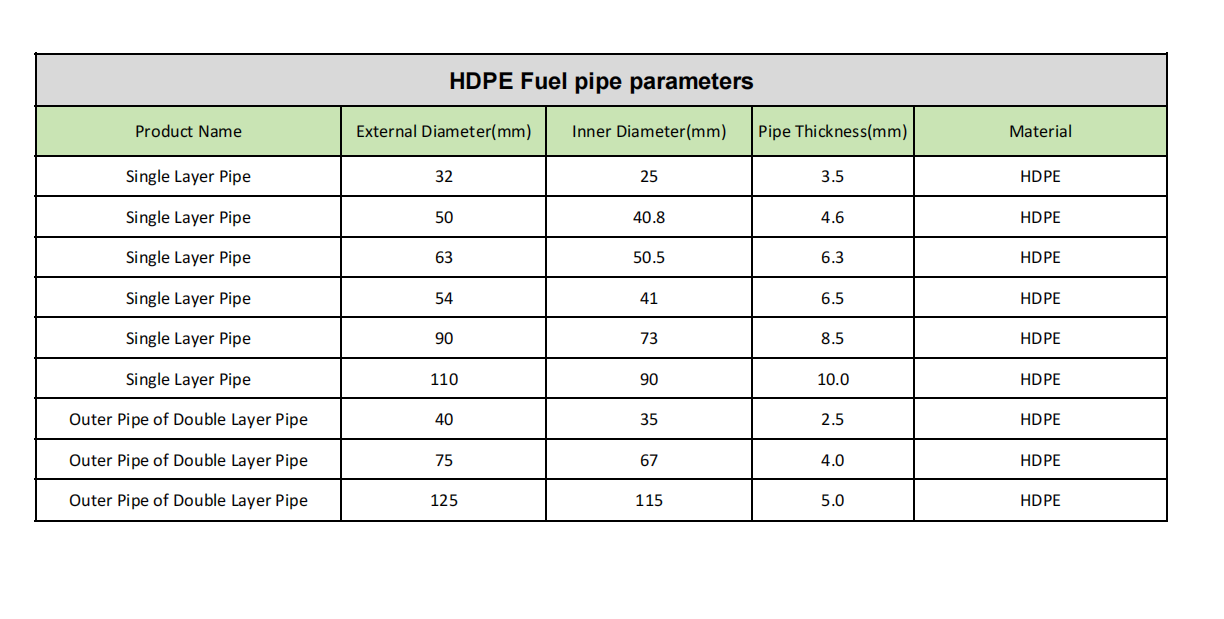

Our 90 Degree Elbow Double Wall HDPE Pipe Fittings are available in a range of sizes to meet the needs of businesses of all sizes. Whether you're a small agricultural operation or a large industrial manufacturer, we have the fittings you need to ensure that your pipeline system works efficiently and effectively. Additionally, our fittings are easy to install, minimizing the amount of time and labor required to get your pipeline system up and running.

Overall, the 90 Degree Elbow Double Wall HDPE Pipe Fittings are an excellent choice for businesses looking to improve the performance and efficiency of their pipeline systems. With their weather-resistant design, dual-walled construction, and high-quality materials, our fittings are an investment in the long-term performance of your business. So why wait? Contact us today to learn more about our fittings and how they can benefit your operation.

90 Degree Elbow Double Wall HDPE Pipe Fittings

How do you choose the right petrol station pipeline?

Why PE flexible pipeline not traditional steel pipeline?

1. Within -40℃~50℃ temperature range, the burst pressure of PE flexible pipeline which is over 40 standard atmospheric pressure protect the pipeline to perform durably.

2. The efficient Electro fusion welding techniques connect pipe with its accessories and produce a seamless buried oil-supply pipeline system.

3. The pipeline can eliminate all the leakage from oil tank to fuel dispenser, thus protecting the environment. It prevents the underground water from permeating into the pipe.

4. PE pipeline with polytene composite material can be used for all kinds of fuel, ethanol mixture and additives. According to EN14125 standard testing and proving, the pipe can apply to hydrocarbon, ethanol fuel mixture and biofuel at 10 standard atmospheres of pressure (bar)

5. Excellent static conductivity demonstrates the PE flexible pipeline with high safety performance.

6. No need concrete furrow. It can significantly reduce the construction cost for fuel station.

7. Easy installation with rich choice for accessories provides the flexibility of pipeline direction.

Gas Fuel Filling Station Plastic Flexible HDPE PE Pipe for Fuel Dispenser Gasoline Petrol Station Pipe Fitting Equal Pipe.

A double wall HDPE pipe 90 degree elbow is a fitting used to connect two pieces of double wall HDPE pipe at a 90 degree angle. The double wall HDPE pipe is made up of two layers of high density polyethylene, which provides considerable strength and durability, making it ideal for use in underground or aboveground applications. The 90 degree elbow allows the pipes to change direction without the need for additional fittings or piping. These fittings are commonly used in applications such as storm water management, sewer systems, and agricultural irrigation systems. They are also resistant to abrasion, corrosion, and chemicals, ensuring long-term strength and performance.

Our team is dedicated to providing the best service possible, and we strive to exceed customer expectations.

The company specializes in 90 Degree Elbow Double Wall HDPE Pipe Fittings product production, research and development and sales

Our pipes are easy to install and require minimal maintenance.

Our company continuously updates and improves product production every year, and now has a professional production line developed by ourselves. The product quality and service are far ahead of other manufacturers in the 90 Degree Elbow Double Wall HDPE Pipe Fittings market.

Our underground fuel transfer pipes are manufactured with precision and care.

The company will do its best to create tailor-made products for customers and meet customer needs at appropriate prices.

Our pipes are compatible with a wide range of fuels, from diesel to gasoline to ethanol.

Humanized design based on people is the tenet and goal of our product design.

Our pipes are made of durable materials that hold up well under the harshest environmental conditions.

The purpose of our company is: integrity is the foundation of business, efficiency is the premise of survival, development is for better survival, and return is our responsibility.

Hot tags:double wall hdpe pipe, double wall upp pipe, single wall upp pipe, kps pipes, petrol hdpe pipe bend, upp pipe bend fitting, opw type hdpe fuel pipe, China, customized, discount, manufacturers, factory, price, for sale, suppliers