As a manufacturer of high-quality products, we are proud to offer our customers the Fuel Tanker Gauge Hatch. This product is designed to meet the needs of merchants who need a reliable and efficient way to monitor fuel levels in their tanker trucks.

The Fuel Tanker Gauge Hatch is an innovative product that is designed to make the fuel monitoring process more efficient than ever. It consists of a hatch that is installed on the top of the fuel tanker, which provides easy access to the tank's contents. The hatch is equipped with a gauge that provides accurate readings of the fuel level, so merchants can quickly and easily monitor their fuel consumption.

One of the key features of the Fuel Tanker Gauge Hatch is its durable and high-quality construction. The hatch is made from high-quality materials that are designed to withstand the harsh conditions that come with long hauls and the demands of the fuel transportation industry. The gauge itself is made from high-grade materials that are resistant to corrosion, so it can withstand exposure to harsh chemicals and other substances.

The Fuel Tanker Gauge Hatch is also incredibly easy to use. It is designed to be easily installed on the top of the fuel tanker, and the gauge is straightforward and intuitive to read. Whether you are an experienced fuel transport professional or new to the industry, the Fuel Tanker Gauge Hatch is a reliable and easy-to-use tool that can help you get the job done.

In addition to its durability and ease of use, the Fuel Tanker Gauge Hatch is also incredibly accurate. The gauge is designed to provide highly accurate readings, so merchants can trust that they are getting reliable data about their fuel levels. This accuracy is crucial in the fuel transportation industry, where even small discrepancies in fuel levels can have a significant impact on costs and efficiency.

The Fuel Tanker Gauge Hatch is also designed with safety in mind. It features a locking mechanism to prevent unauthorized access to the tank, which can help prevent accidents and spills. The hatch also includes various safety features, such as pressure relief valves, that help ensure that the tank is not overfilled or damaged during operation.

Another benefit of the Fuel Tanker Gauge Hatch is that it can help merchants save money. Accurate fuel monitoring can help identify inefficiencies and areas where fuel consumption can be reduced, which can help save money on fuel costs over the long term. Additionally, the durability and reliability of the Fuel Tanker Gauge Hatch means that merchants can extend the lifespan of their tanker trucks and other equipment, saving money on repairs and replacements in the long run.

Overall, the Fuel Tanker Gauge Hatch is an excellent product for merchants who are looking for a reliable, efficient, and accurate way to monitor fuel levels in their tanker trucks. With its high-quality construction, ease of use, safety features, and money-saving potential, the Fuel Tanker Gauge Hatch is sure to be a valuable investment for any fuel transport professional.

Measure Device Rotary Gauge Dip Hatch

Best Tank Truck Aluminium Alloy Rotary Gauge Hatches Tank Truck Aluminium Alloy Rotary Gauge Hatch

Usually installed on the top of the oil truck,used to measure inside oil level,test,temporary and take samples. hatch use aluminium alloy body,there is a measure rule slot inside it,when taking measure of the oil level,it will prevent the rule glide cause the spark to keep the oilcan safety.

The gauge hatch is divided into a pedal type and a rotary type. It is installed on the top of the oil tank and is used to measure the elevation and temperature of the oil in the tank and the sampling. Because the chemical materials have different degrees of harmful odor, they cannot be discharged to the atmosphere during measurement. in. In order to complete the measurement procedure and ensure that it is not affected and operated by the operator, the Gauge hatch can play a role in this aspect.

The Gauge hatch is installed on the top of the tank and can be sealed at ordinary times. When measuring the chemical, first unscrew and measure the port seal, tighten the middle of the narrow-mouth measuring component cover, and then press the middle seal operation handle. The cylinder seal can be opened, and the level of the liquid level can be measured by slitting the measuring ruler from above. After the operation is completed, pull back the handle, take out the measuring component, and put it into the seal to tighten. For the measurement and sampling of the oil, pull down the middle operating handle and open the upper cover.

The Gauge hatch is often opened and closed, and it is easy to be damaged and leaks. Therefore, the tightness should be regularly verified. During the identification, apply a thin layer of paint on the edge of the hole, gently cover the hole cover, and apply a certain force by hand.

THERE ARE TWO TYPES GAUGE HATCHS:

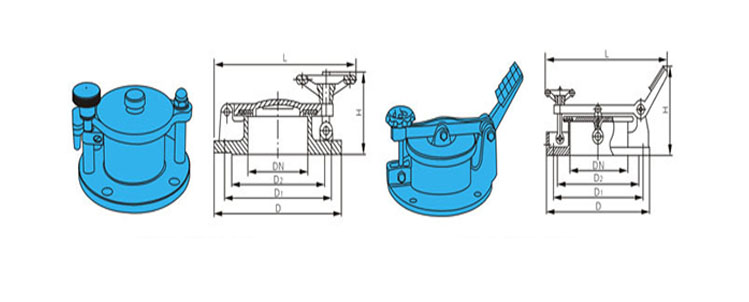

TYPE 1——Rotary Gauge hatch

Rotary Gauge hatch is a special accessory used to measure the oil level in the tank and to pick up the oil sample. One of the tops of each tank is located, mostly located near the tank platform. The fire in the oil tank often occurs in the measuring hole. The main reason is that when the measuring operation, the hole cover opens the oil and gas in the tank, and if the static spark or the impact friction sparks, the fuel gas will catch fire.

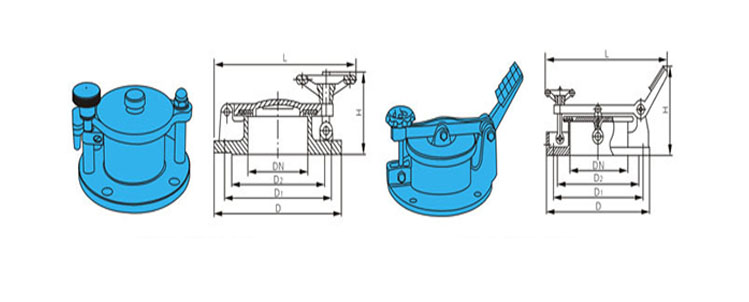

TYPE 2——Pedal Gauge hatch

Pedal Gauge hatch is installed on the top of the oil tank to measure the elevation and temperature of the oil in the tank and the sampling. The chemical materials have different degrees of harmful odor and cannot be discharged into the atmosphere during measurement. In order to complete the measurement procedure and ensure that the environment is not affected and the operator is safe to operate, the oil hole can play a role in this.

Structural features and working principle:

The (4 inch / 6 inch) Gauge hatch is mainly composed of a valve body, a rotary latch, a tensile kidney, a sealing cover, a rolling bolt, and a hand wheel.

The Gauge hatch is used to ensure the measurement error every time the oil is cut along the same position, and the aluminum or copper guide groove is installed on one side of the inner wall of the oil hole. There should be no welds on the bottom of the tank below the oil hole. If necessary, a gauge plate can be welded there to reduce the relative error of each measurement. The measuring hole has a diameter of 100 mm and is provided with a closed hole cover and a loose bolt. In order to prevent the hole cover from colliding with the iron to generate spark when closing, an oil-resistant rubber pad or soft metal (copper or aluminum) is embedded in the sealing groove of the hole cover. ). Since the steel tape measure for measuring is easy to rub and generate sparks, a copper (or aluminum alloy) sleeve is placed inside the hole tube, or a non-ferrous metal guide groove (a measuring groove) which does not generate sparks is installed outside the fixed measuring point. . The oil hole is often opened and closed, and it is easy to be damaged and leaks. Therefore, the tightness should be regularly verified. During the identification, apply a thin layer of paint on the edge of the hole, gently cover the hole cover, and add a certain force by hand. If the village pad has obvious traces, it can be considered qualified. If the trace is incomplete, the hole cover is not tight and the gasket should be replaced.